Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Mr. John.zhou

What can I do for you?

Model No.: 800mm

Brand: IDO

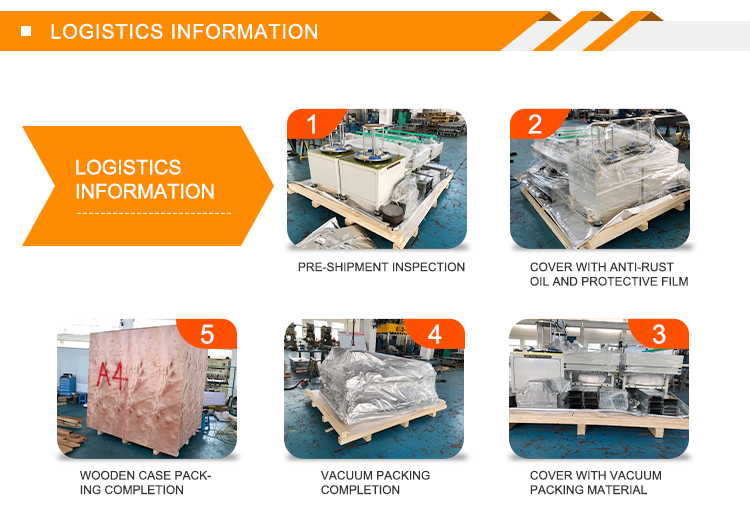

Transportation: Ocean,Air

Place of Origin: WUXI CHINA

Port: Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB

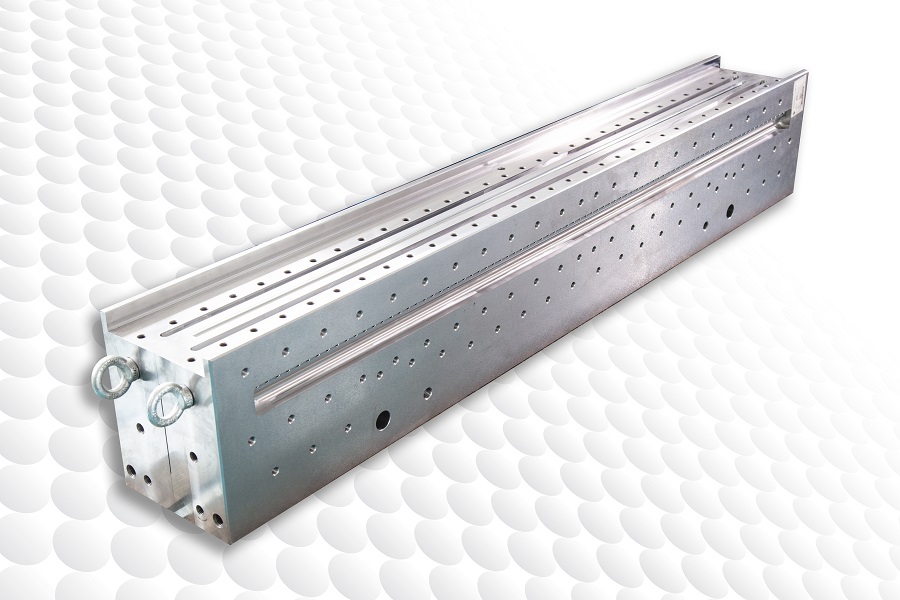

800mm Melt Blown Non-woven Fabric Precision Machine Die

Provide FFP2, FFP3 high quality Melt Blown Non-woven Fabric production One-Step solution

| Melt-Blown Non-Woven Fabric Die Technical Parameters | |

| Specifications | Date |

| production name | melt-blown filter material |

| GSM Range | 20~45g/㎡ |

| Fiber Fineness | 2~5μm |

| Raw Material | MFI=1200~1800 polypropylen |

| Product Specification | 0.8m width |

| Installed Power | 850KW |

| Maximum Mechanical Speed | 0.8m/min |

| Production Capacity | 80kg/h~120kg/h |

| Space Required | 5mx10mx3m |

| Service Environmen | Dust-free workshop or workshop in line with national |

| standards for production materials | |

| Size | |

| Slope angle | 60° |

| Spinneret orifice diameter | 0.25±0.002mm |

| Center-to-center distance | 0.56mm |

| between holes | |

| Spinneret orifice length | 4mm |

| Length-diameter ratio | 16 |

| Hole density (holes within 1 inch) | 46nos |

| Hole arrangement length | 820mm |

| Nozzle clearance | 1mm |

| Nozzle height | 1mm |

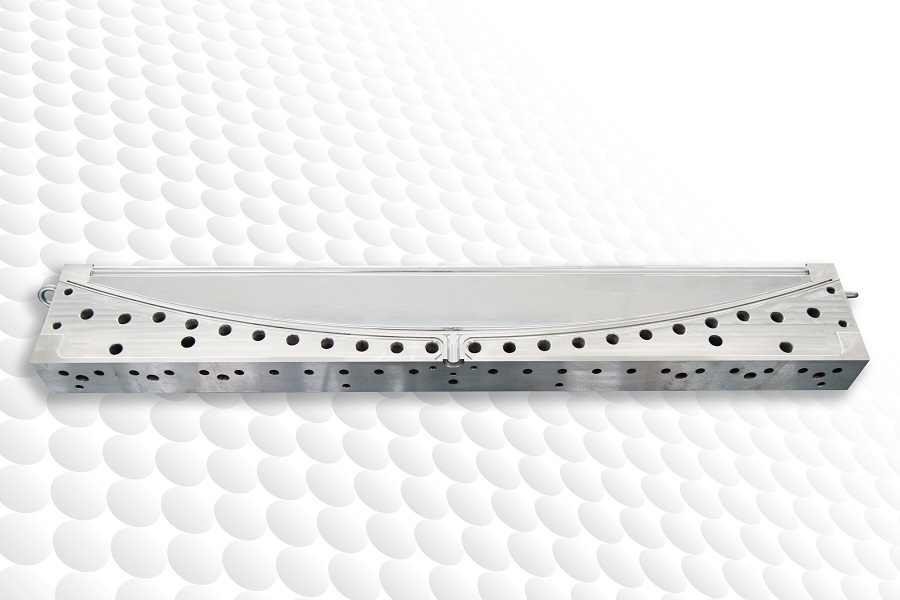

1. The precise CMM ensures the precise machining to meet the requirements.

2. The runner is polished by mirror and the surface is plated with hard chrome, and the die head is secondary homogenized to make the material flow smooth and even

3. Clean oil and garbage with ultrasonic equipment before testing spinneret.

4. The 2,746 holes were examined one by one with 200 times magnification of electron microscope.

Product Categories : Melt-Blown Non-Woven > Melt Blown Nonwovens Fabric Mould

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.