Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Mr. John.zhou

What can I do for you?

Model No.: 600mm

Brand: IDO

Transportation: Ocean,Air

Place of Origin: WUXI CHINA

Certificate: CE

Port: Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB

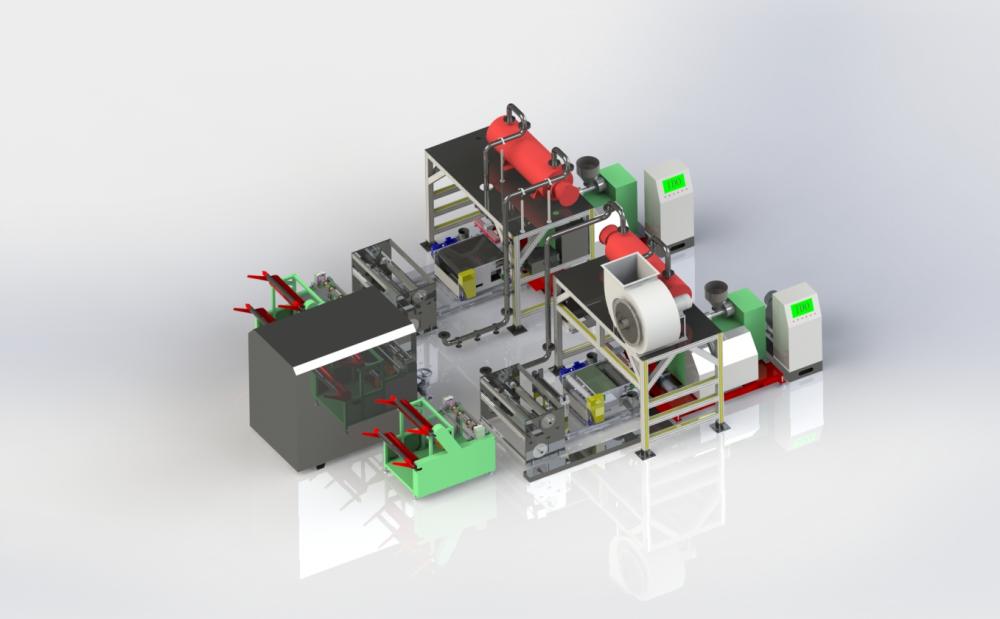

RP-600 melt blown Nonwoven fabric production line Can Make FFP2 Quality

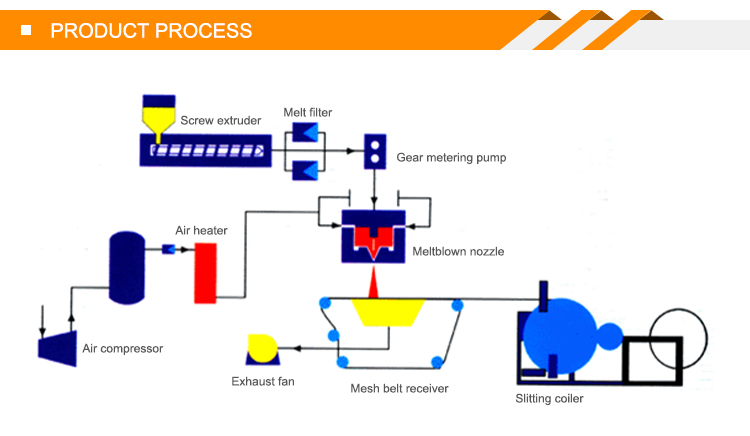

PP Melt Blown Nonwoven Fabric Manufacturing Process

The melt-blown nonwoven making process uses high-speed hot air to draw a thin stream of polymer melt extruded from the spinneret of the die, thereby forming ultra-fine fibers and condensing on the curtain web, and relying on self-adhesion to become non-wovens.

What is melting spray?

At present, the production process of melt spraying cloth, the raw material for the manufacture of medical masks, is needed. So what is melt spraying?

Melt spraying is a conventional method for fabricating fibers and self-bonded mesh (nonwoven fabric).

The main advantages of melting spray are its simplicity and high productivity.

One popular use of non-woven fabrics is masks.

What is the PP melt-blown nonwovens process?

To make it easier to understand, we will show you the melting spray technology in six aspects.

PP melting and extrusion

• The screw extruder sends the polypropylene (PP) melt to the melt die head assembly and extrudes it from the spinneret hole of the die head.

Melt filter

• Clean the PP melt after filtration for better molding.

Uniform melt transport

• After the PP melt is cleaned and filtered, the melt is continuously and uniformly transported to the spinneret through accurate metering of metering pump to control output and fiber fineness.

Fiber forming

• At the same time of extrusion of PP melt through spinneret hole, the melt flow is drawn through high-speed hot air flow to form extremely fine short fibers.

| Scope of application and preparation for production line | ||

| NO. | Item | Data |

| 1 | Coil width | 600mm (175mm*3, adjustable) |

| 2 | Coil length | 2000m |

| 3 | Gram weight range | 25-45g/㎡ |

| 4 | Production capacity | 300kg/day |

| 5 | Total power | 150KW |

| 6 | Power supply voltage | 380V 50HZ+/-10% |

| 7 | Air source pressure | 5bar-7bar |

| 8 | Space required | 7m*3m*3.1m |

| 600mm Meltblown Nonwoven Fabric Major Equipment List | ||||

| NO. | Name | Unit | Quantity | Remarks |

1 | Screw extruder machine | set | 1 | With section heating measurement |

2 | Meltblow nonwoven into net receiver | set | 1 | hydraulic drive, automatic switching |

3 | Metlblown roll cutting rewinding machine | set | 1 | Customized die |

4 | Meltblown nonwoven fabric mould | set | 1 | 3 coils synchronize |

5 | Single screw blower | set | 1 | 37KW、380V、120KPA、13m3/Min |

6 | Electrical integrated control system | set | 1 | Schneider Servo-driven precise control |

7 | Electrostatic electret processor | set | 1 | 1000mm/1200mm |

Product Categories : Melt-Blown Non-Woven > Melt Blown Nonwovens Automatic Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.