Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Mr. John.zhou

What can I do for you?

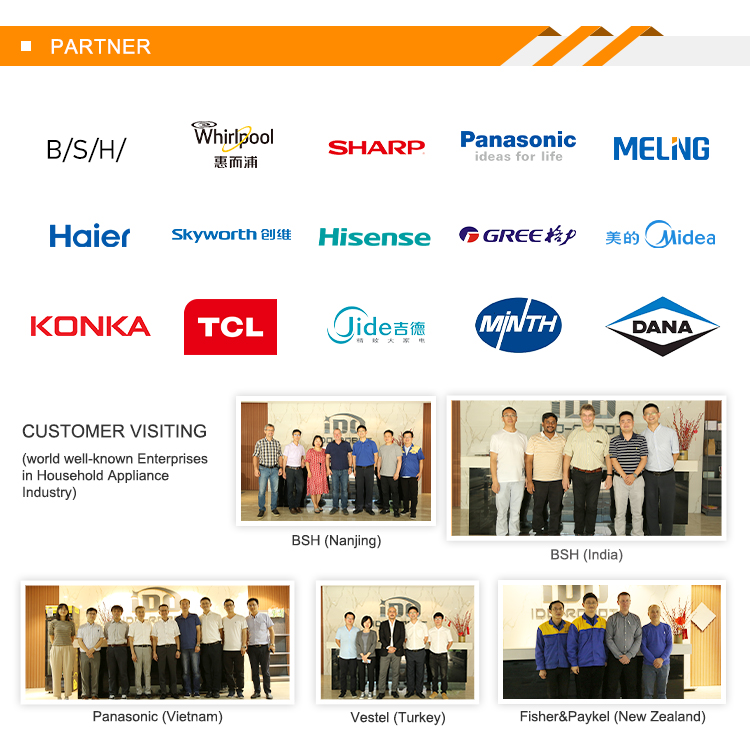

Brand: IDO

Certification: ISO

Automation: Automation

Flexible Production: Intelligent Manufacturing

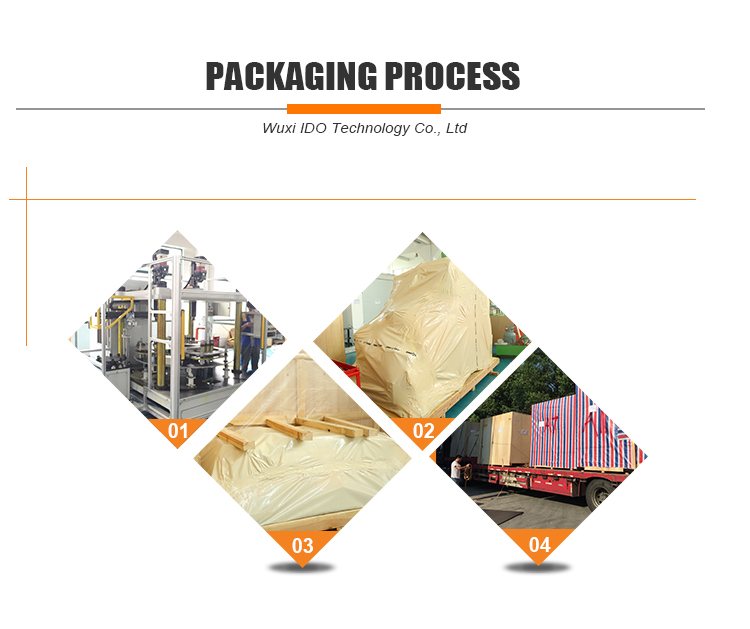

Packaging: wooden box

Transportation: Ocean

Place of Origin: CHINA

Certificate: ISO9001:2015

Port: Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB

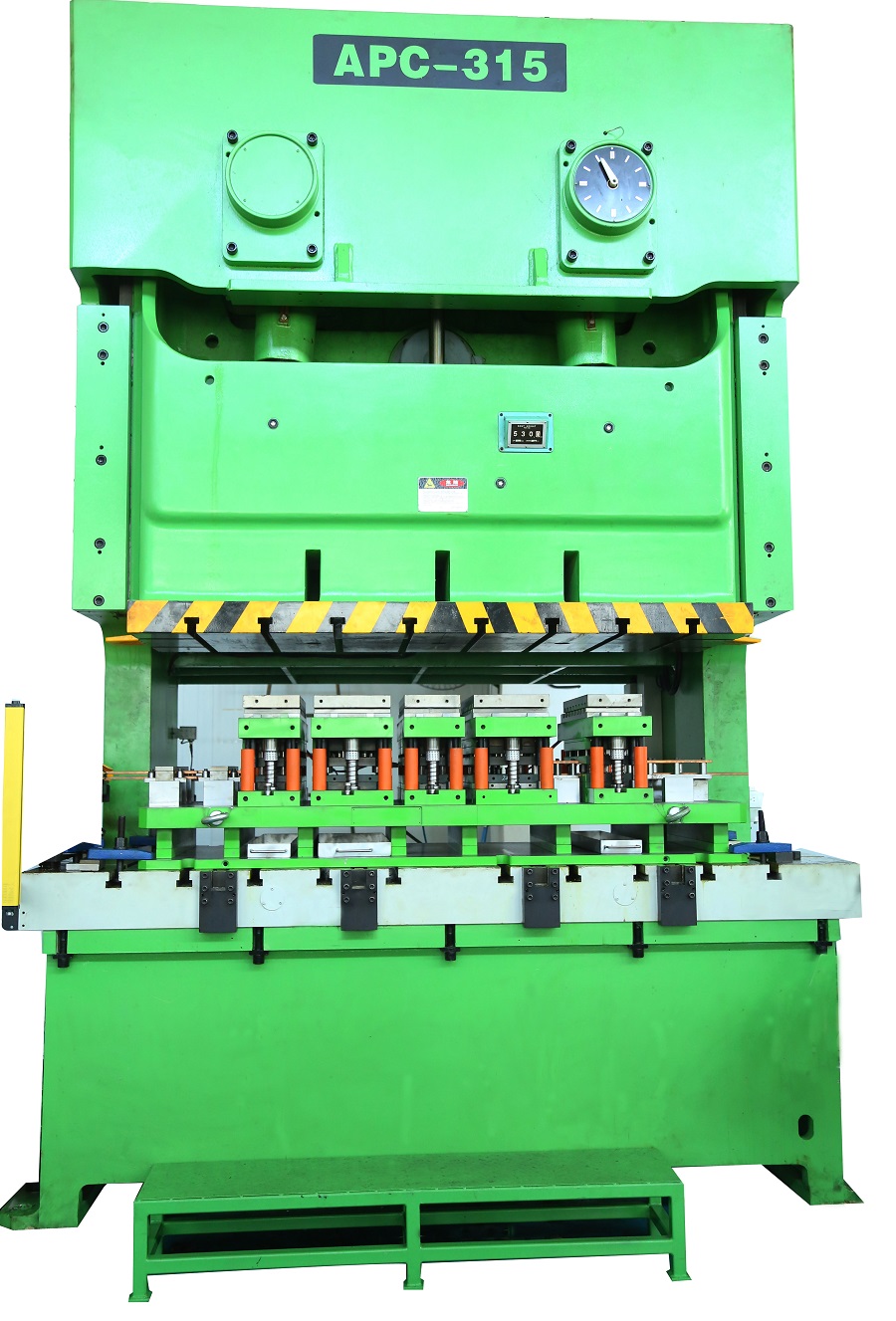

Automatic stamping equipment and die

1、Automatic stamping includes a two-point mechanical punching machine, which can punch, press and cut off the inner cylinder sheet.

2、The tonnage, table surface, clamping height, etc., shall be within the range of the largest specifications of Party A's products, and the minimum tonnage shall be 300T or above, which shall be convenient for maintenance and repair operation;

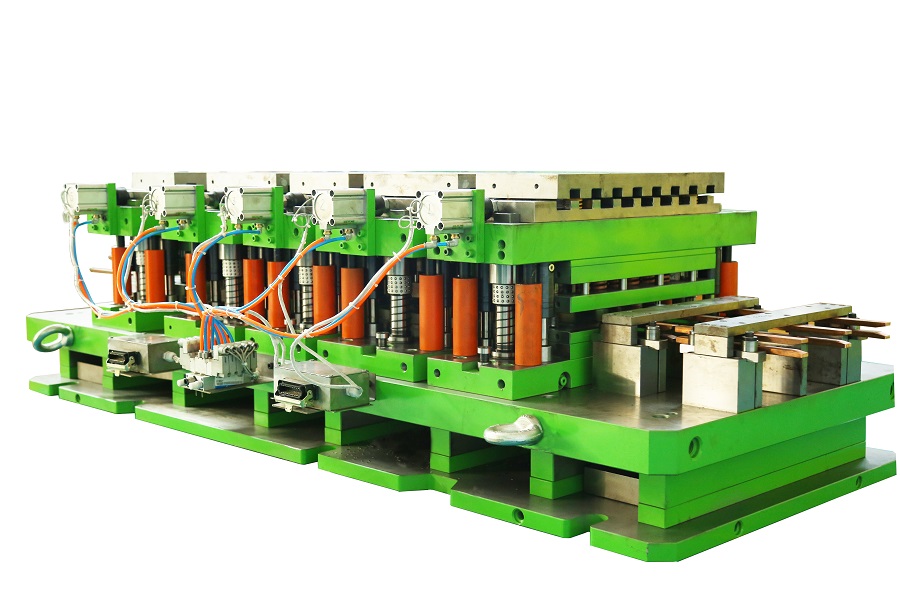

3、The mold is replaced by a quick automatic in-and-out mold push and pull system and a quick positioning system. The interface between the mold and the equipment needs to adopt a quick plug and pull structure. At the same time, effective identification and error prevention device should be adopted for the switch of each model to avoid the risk of problems caused by the mold or the material sheet not in place, so as to facilitate the staff to correct the operation.

4、The sheet guide limit device should be set in the mold to avoid the sheet deformation or position deviation in the stamping or transfer process.At the same time, all parts in contact with the product sheet should be polished to avoid scratches on the surface of the product and other undesirable appearance defects;

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Categories : Washing Machine > Front-Loading Drum Automation&Assembly Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.